Executive Stainless Steel products consist of high quality solid wires, flux cored wires and coated electrodes, all with excellent operator appeal.

The executive line of Stainless Steel

Download

Product Catalog

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- All

- Solid Wire

- Cored Wire

- Coated Electrode

- Executive 16-8-2

- Executive 218

- Executive 2209

- Executive 2594

- Executive 307Si

- Executive 308H

- Executive 308/308L

- Executive 308Si/LSi

- Executive 309/309L

- Executive 309Si/309Lsi

- Executive 309LMo

- Executive 316/316L

- Executive 316Si/316LSi

- Executive 310

- Executive 312

- Executive 317/317L

- Executive 320LR

- Executive 330

- Executive 347

- Executive 385

- Executive 409Nb

- Executive 410

- Executive 410NiMo

- Executive 420

- Executive 430

- Executive 439TiCu

- Executive 630 (17/4 PH)

- Executive 2209P

- Executive 308/308L

- Executive 308/308LP

- Executive 309/309L

- Executive 309/309LP

- Executive 309LMo

- Executive 316/316L

- Executive 316/316LP

- Executive 330

- Executive 347

- Executive 410NiMoP

- Executive 16-8-2-16

- Executive 2209-16 (Duplex)

- Executive 2594-16 (Super Duplex)

- Executive 308/308L-16

- Executive PLUS 308/308L-17

- Executive 309/309L-16

- Executive PLUS 309/309L-17

- Executive 316/316L-16

- Executive PLUS 316/316L-17

- Executive 310-16

- Executive 312-16

- Executive 317/317L-16

- Executive 330-16

- Executive 347/347H-16

- Executive 410-16

- Executive 410NiMo-16

- Executive 439Ti-MC

Executive 410 provides superior weldability, low spatter and smooth beads with easy slag removal. Weld metal is suitable for welding AISI 410 and AISI 420 types of stainless steel. This 12 Cr alloy is an air-hardening steel. Preheat and postheat treatments are required to achieve welds of adequate ductility for many engineering purposes. The most common application of these electrodes is for welding alloys of similar compositions. They are also used for surfacing of carbon steels to resist corrosion, erosion or abrasion.

Application and Features

Maintains excellent oxidation and corrosion resistance at high temperature. Obtains high hardenability after welding. Suitable for applications in petro-refining and chemical industries.

Typical Wire Chemistry and Mechanicals

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.019 | 0.54 | 0.29 | 0.031 | 0.007 | 13.32 | 0.20 | 0.04 | 0.05 |

| Tensile Strength: | 74,000 PSI min | Elongation: | 28% |

| Yield Strength: | 46,400 PSI min |

Typical Welding Parameters

| Process | Diameter | Length | Amperage |

|---|---|---|---|

| SMAW | 3/32" | 12" | 40-70 |

| AC/DC | 1/8" | 14" | 60-100 |

| 5/32" | 14" | 90-140 | |

| 3/16" | 14 | 120-185 |

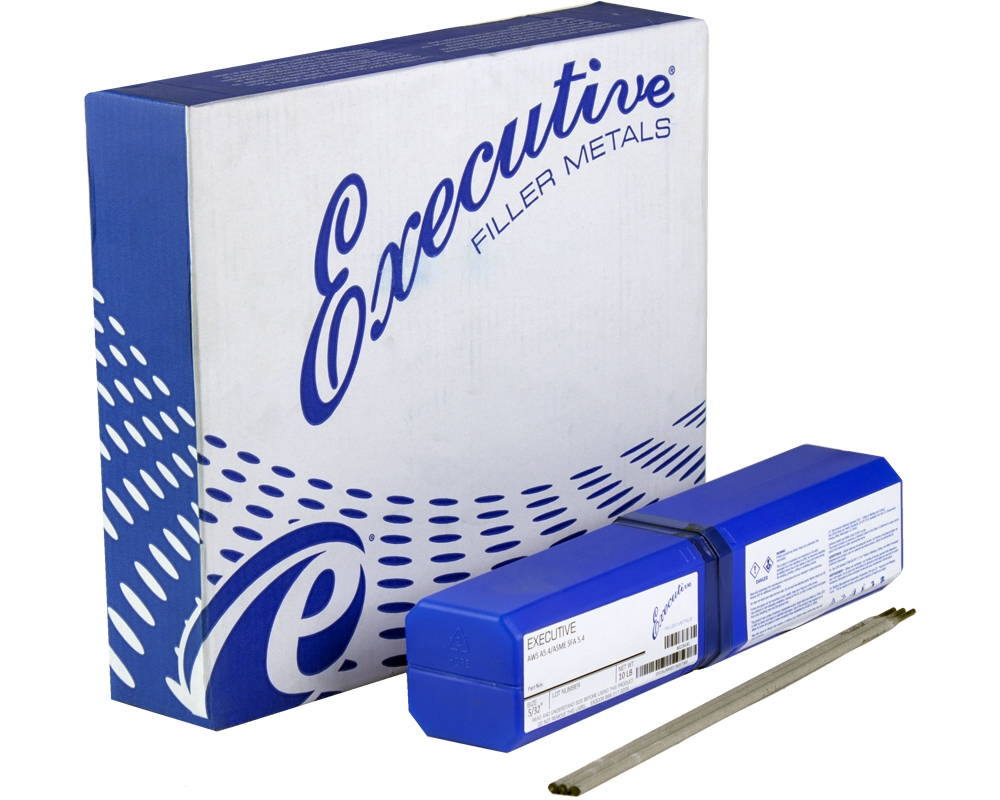

Standard Packaging

| SMAW | 40-lb master box |

| 10-lb plastic tube |

Classification

AWS/SFA 5.4, Class E410-16

- Home

- News

- Contact us

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- Find a Distributor

- Become a Distributor

©2024 Executive Filler Metals. All Rights Reserved.