Executive Stainless Steel products consist of high quality solid wires, flux cored wires and coated electrodes, all with excellent operator appeal.

The executive line of Stainless Steel

Download

Product Catalog

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- All

- Solid Wire

- Cored Wire

- Coated Electrode

- Executive 16-8-2

- Executive 218

- Executive 2209

- Executive 2594

- Executive 307Si

- Executive 308H

- Executive 308/308L

- Executive 308Si/LSi

- Executive 309/309L

- Executive 309Si/309Lsi

- Executive 309LMo

- Executive 316/316L

- Executive 316Si/316LSi

- Executive 310

- Executive 312

- Executive 317/317L

- Executive 320LR

- Executive 330

- Executive 347

- Executive 385

- Executive 409Nb

- Executive 410

- Executive 410NiMo

- Executive 420

- Executive 430

- Executive 439TiCu

- Executive 630 (17/4 PH)

- Executive 2209P

- Executive 308/308L

- Executive 308/308LP

- Executive 309/309L

- Executive 309/309LP

- Executive 309LMo

- Executive 316/316L

- Executive 316/316LP

- Executive 330

- Executive 347

- Executive 410NiMoP

- Executive 16-8-2-16

- Executive 2209-16 (Duplex)

- Executive 2594-16 (Super Duplex)

- Executive 308/308L-16

- Executive PLUS 308/308L-17

- Executive 309/309L-16

- Executive PLUS 309/309L-17

- Executive 316/316L-16

- Executive PLUS 316/316L-17

- Executive 310-16

- Executive 312-16

- Executive 317/317L-16

- Executive 330-16

- Executive 347/347H-16

- Executive 410-16

- Executive 410NiMo-16

- Executive 439Ti-MC

Executive PLUS 316/316L-17-Safety Data Sheet

Download

Executive PLUS 316/316L-17-Data Sheet

Download

Executive PLUS electrodes have a unique European formulation designed for the most discriminating operator. Improved silica-titania (AC-DC) coating resists moisture pick up. A careful selection of raw materials and an advanced manufacturing process guarantees the electrodes resist starting porosity; even under extreme humidity and when left exposed to the atmosphere for prolonged periods. Noble chemistry improves corrosion resistance in challenging environments and actual weld deposit chemistries as well as controlled ferrites with each batch.

Executive PLUS 316/316L provides superior weldability, low spatter and smooth beads with easy slag removal and can be used in all positions when welding as root runs in butt welds and thin plates in general. This low-carbon alloy, however, is not as strong at elevated temperatures as Type E316H.

Application and Features

Executive PLUS 316/316L-17 electrodes are used principally for welding low-carbon, molybdenum-bearing austenitic alloys. Executive PLUS features include: high current-carrying capacity, a smooth finely rippled weld bead, self-detaching slag with no residue, elimination of starting porosity, superior arc stability with excellent strike and restrike characteristics.

Typical Wire Chemistry and Mechanicals

| C | Cr | Ni | Mo | Mn | Si |

|---|---|---|---|---|---|

| <0.025 | 18.5 | 11.5 | 2.8 | 0.8 | <0.8 |

| Tensile Strength: | 79,000 PSI min | Elongation: | 39% |

| Yield Strength: | 49,000 PSI min | Charpy V-Notch: | 44 ft/lb at -76°F / -60°C |

Typical Welding Parameters

| Process | Diameter | Length | Amperage |

|---|---|---|---|

| SMAW | 3/32" | 12" | 40-70 |

| AC/DC | 1/8" | 14" | 60-100 |

| 5/32" | 14" | 90-140 | |

| 3/16" | 14 | 120-185 |

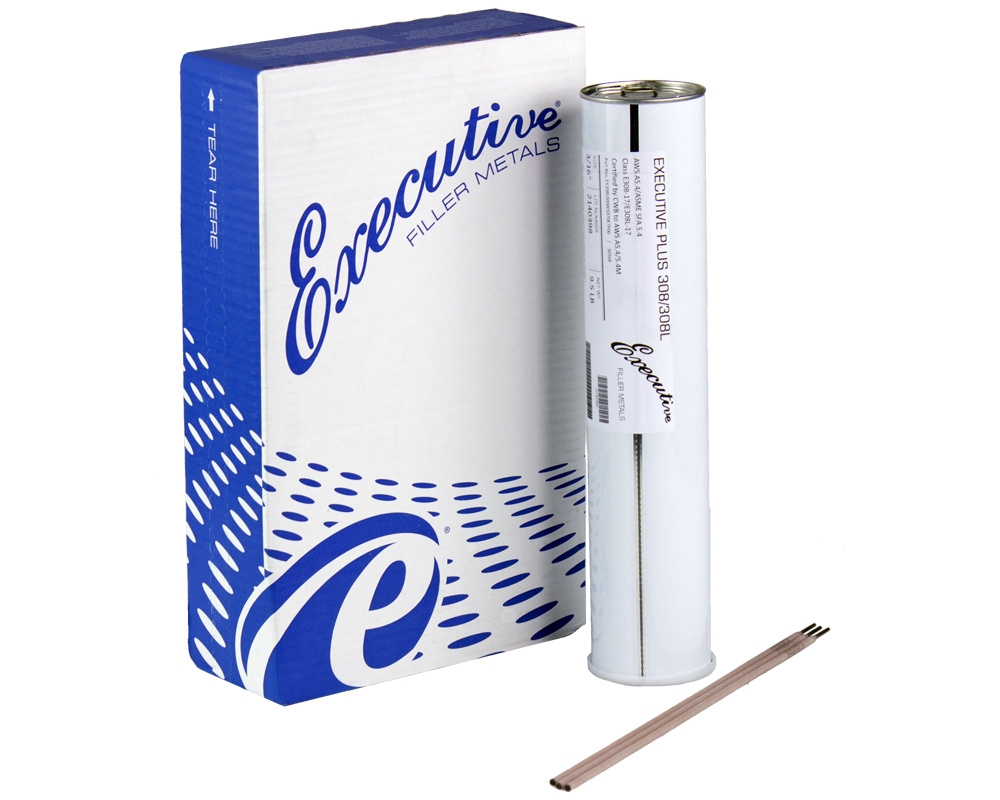

Standard Packaging

| SMAW | 3/32" | 9-lb metal can | 27-lb master box |

| 1/8" | 9-lb metal can | 27-lb master box | |

| 5/32" | 9.5-lb metal can | 28.5-lb master box | |

| 3/16" | 9.5-lb metal can | 28.5-lb master box |

Classification

AWS/SFA 5.4, Class E316/316L-17

Certified by the Canadian Welding Bureau (CWB) to AWS A5.4

- Home

- News

- Contact us

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- Find a Distributor

- Become a Distributor

©2024 Executive Filler Metals. All Rights Reserved.