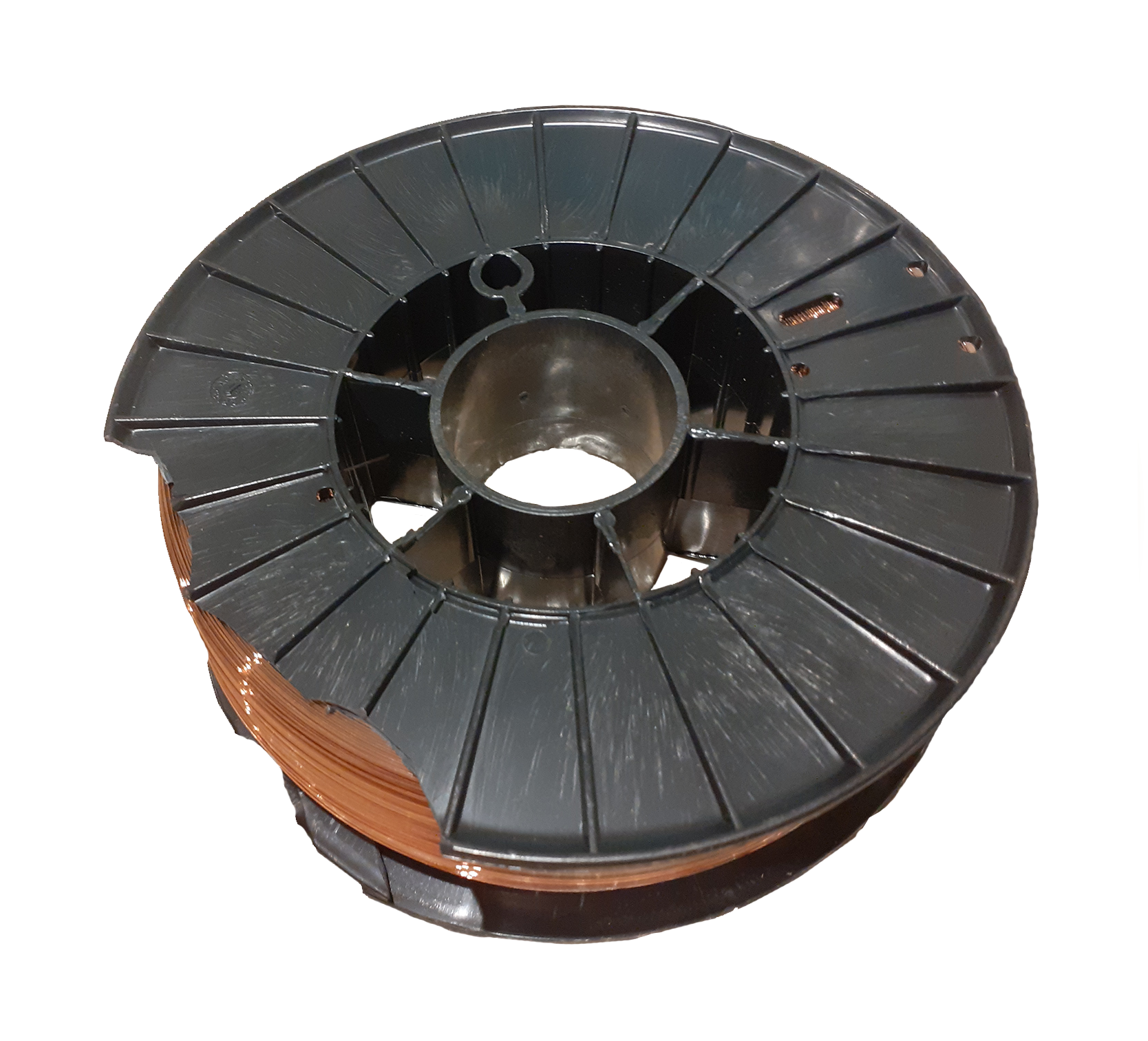

Precision winding is the process of layering wire during manufacturing to ensure that it stays tightly wound around the spool hub with no chance of tangling. Executive filler metals are precision wound on both plastic spools as well as wire baskets.

Preventing Wire Tangling 3-23.pdf

Download

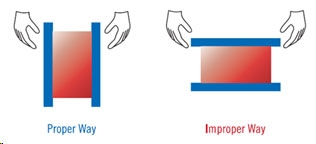

Lifting the Spool Incorrectly

When lifting or carrying a heavy spool while holding it sideways by the flange, the flexing forces can disturb the layering of wire. The deformation of the spool wall will cause voids to form beneath the surface of the wire causing potential for a misalignment of the layers and ultimately tangling.

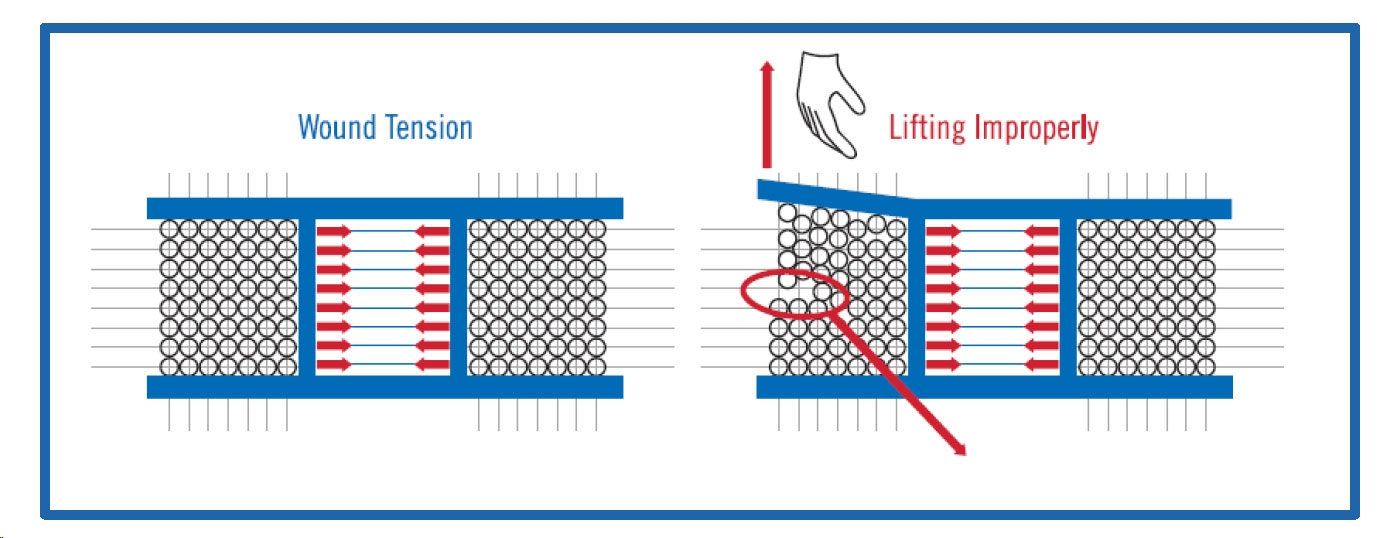

Excessive Brake Tension

Excessive brake tension can compound a problem for a spool that has been lifted incorrectly causing wire tangling. As the wire runs off near the edge of the spool, the brake force shifts and pulls the wire down, into the voids created by the deformation of the spool due to improper handling.

Hand Winding

Manually re-winding spools by hand can seriously affect the tension of the remaining wire affecting the subsequent layers, occasionally being a cause of tangling. Proper practice is to cut off the excess wire near the source spool while holding the loose end firmly and then re-attach it to the spool.

Dropping the Spool

Plastic spools or wire baskets are not designed to withstand being dropped. In addition to possibly breaking the spool outright, hitting the ground can disturb the layers of wire which leads to tangling.

IMPROPER HANDLING TECHNIQUES CAUSE TANGLING OF SPOOLED WIRE

- Lift spools properly by the flange in the vertical position (Figure 3)

- Ensure your brake is not too tight

- When done, cut the wire at the spool and re-tie it on the spool

- Do not drop spools of welding wire

- Home

- News

- Contact us

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- Find a Distributor

- Become a Distributor

©2024 Executive Filler Metals. All Rights Reserved.