Since welding wires are mechanically formed or drawn, they naturally retain some springback, which is defined by their cast and helix, critical physical characteristics that affect wire feedability, arc stability, and overall weld quality.

Cast and Helix.pdf

Download

What is Cast?

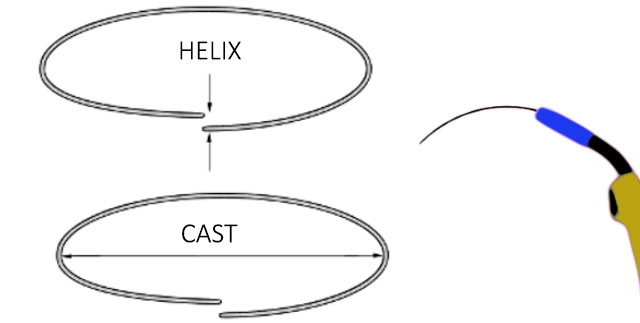

Cast refers to the natural curvature of the welding wire when a section is cut and laid flat on a surface. It is measured as the diameter of the circle the wire forms.

- Larger cast (a bigger circle) allows for smoother wire feeding and reduces friction inside the welding liner, leading to more consistent feeding and less chance of bird-nesting or wire tangling.

- Smaller cast (a tighter circle) can be beneficial in some applications where tighter wire control is needed, but too small a cast may cause feeding issues and premature wear on the wire feed system.

What is Helix?

Helix refers to the vertical rise of the wire when a cut section is laid on a flat surface. If the wire does not lay completely flat but instead has a spiral effect, it has a higher helix.

- Minimal helix ensures the wire feeds in a straight, controlled path through the gun, preventing issues like wandering arcs and inconsistent bead placement.

- Excessive helix can lead to erratic wire feeding, poor arc stability, and irregular weld deposits.

Cast and helix play a crucial role in wire feeding performance, arc stability, and welder comfort. A well-controlled cast and helix minimize drag and friction within the liner, reducing feed-related stoppages and ensuring smooth, consistent wire delivery. When the wire follows a predictable path, voltage and amperage remain steady, which helps maintain arc stability. The American Welding Society (AWS) specifies tolerances for both cast and helix in its standards for welding filler metals.

For welders using semi-automatic MIG guns, proper cast and helix contribute to better control and reduced hand fatigue. A wire that feeds smoothly and predictably allows for greater precision, making it easier to focus on technique rather than battling erratic wire movement.

Executive Filler Metals are engineered with an optimized cast and minimal helix to improve wire feeding, arc performance, and overall weld efficiency. This consistency in manufacturing production is an Executive hallmark and gives welders more control, reduces downtime from feedability issues, and results in cleaner, more consistent finished welds.

- Home

- News

- Contact us

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- Find a Distributor

- Become a Distributor

©2024 Executive Filler Metals. All Rights Reserved.