Hydrogen Induced Cold Cracking (HICC), often referred to as cold cracking or delayed cracking, is a serious welding-related phenomenon that threatens the integrity of steel welds. It is rooted in the diffusion of atomic hydrogen into the weld and surrounding heat-affected zone (HAZ). When hydrogen atoms dissolve into steel during welding, they can migrate through the metal lattice. As the weld cools, hydrogen’s solubility sharply decreases, especially if the microstructure transforms into a hard, brittle phase such as martensite, which causes the hydrogen to come out of solution. Trapped hydrogen atoms may recombine into molecular hydrogen (H₂) in micro-voids, building internal pressure and promoting crack initiation.

What is Hydrogen Induced Cold Cracking (HICC).pdf

Download

Cracks associated with HICC often appear not immediately during welding, but after some delay (sometimes hours), typically within the first 48 hours, but in some cases up to several days post-weld. These delayed cracks most commonly emerge in ferritic steels and low-alloy steels.

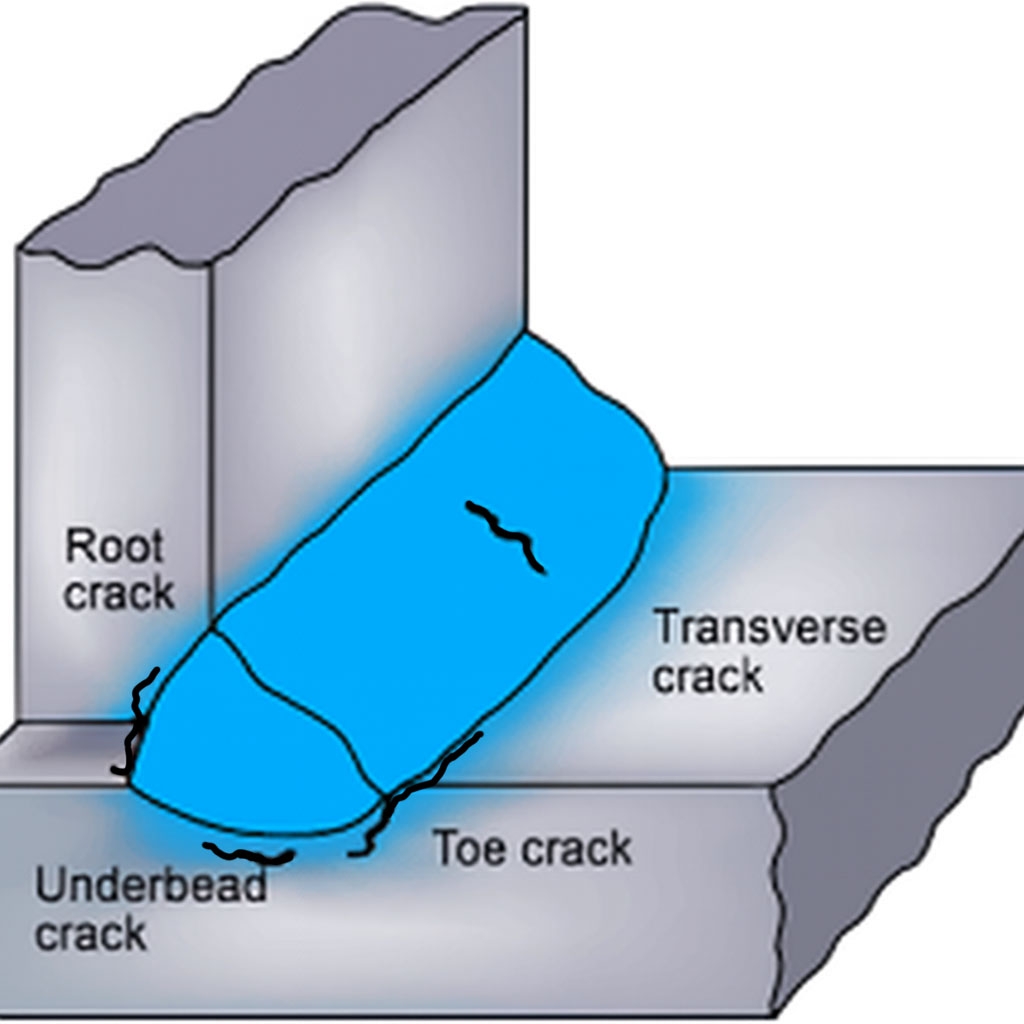

The location and orientation of cracks can vary: in carbon-manganese steels, cracks often originate in the HAZ but may propagate into the weld metal; they can also appear as transverse cracks perpendicular to the weld direction, or as toe, root, or underbead cracks depending on the geometry and stress concentrations.

Preventing HICC requires managing the three key variables of the so-called “hydrogen–stress–microstructure” triangle. Principal strategies include: using controlled hydrogen filler materials such as Executive PLUS 7018-1; carefully controlling preheat and interpass temperatures to slow cooling and avoid formation of hard microstructures; ensuring low residual stresses by minimizing restraint, avoiding misalignment, eliminating gaps or poor backing bar support, and preparing joints properly. Proper storage and handling of consumables (to avoid moisture absorption), prompt baking (post-weld hydrogen bake-out), and allowing an adequate waiting period before inspection or subjecting the welded component to service loads are also widely recommended.

• HICC (cold or delayed cracking) arises when diffusible atomic hydrogen, residual stress, and a crack-susceptible microstructure combine.

• Cracks can occur in weld metal, HAZ, or base metal; common types include transverse cracks, toe, root, or underbead cracks.

• Susceptibility increases with higher strength or alloyed steels, rapid cooling (promoting martensite formation), and high residual stress.

• Prevention centers on reducing hydrogen input (dry electrodes, low-hydrogen processes), controlling weld thermal cycles (preheat, interpass and post-heat), minimizing stress concentrations (good joint fit-up, alignment, backing support), and allowing controlled hydrogen degassing (bake-out or delayed inspection).

- Home

- News

- Contact us

- Stainless Steel

- Carbon Steel

- Nickel Alloy

- Low Alloy

- Aluminum

- Cobalt-Hardfacing

- Executive Line Card

- Find a Distributor

- Become a Distributor

©2024 Executive Filler Metals. All Rights Reserved.